LEARN MORE

ABOUT US

Whitworth's team of experienced machinists and tool and die makers can help with many of your day to day needs whether it be line down, preventative maintenance, refurbishment of existing tools, engineering and design, reverse engineering - your facility or ours, as well as new detail manufacturing with 5-axis and wire EDM capabilities.

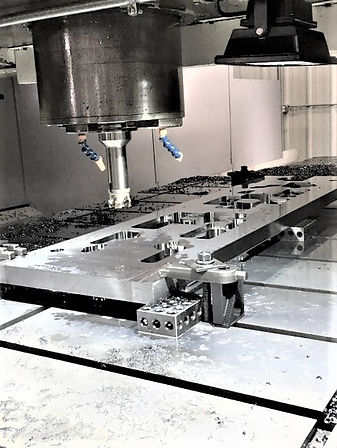

Our state of the art equipment allows machining capabilities for your smallest detail to large components on our largest CNC mill with a machining envelope of 168"x 92" x 58" and 33,000 pound table capacity.

Our quality, turnaround time, and customer service are second to none! Take a look at a few of our many services to reduce your down time whether it be an immediate need or prevention.

Specialty Die Services

Emergency Die Repair

Whitworth Tool prides itself on quick turnaround when your line is down. With our fleet of trucks, we can pick up and deliver to your facility on your timeline 24/7. We can repair or replace it quickly using your blueprints or reverse engineer your sections with our Romer arm capabilities. Our welding capabilities include MIG, TIG, and stick welding. We can weld your die details and get them back in the tool, to get you up and running as soon as possible. Need a trial run prior to return? We have the capabilities with our 500 ton spotting press. Let our experienced tool and die makers take the burden of expensive down time off your shoulders.

Die Maintenance

Whitworth realizes preventative maintenance of tooling is essential to decreasing downtime. Our die maintenance service provides not only quick turnaround, but also coordination with your production schedule to service within your desired timeline. We offer on-site scanning and reverse engineering capabilities to maintain your production and keep your lines running with minimal downtime. Once you can schedule a break in production, we can pick up your tooling and perform the needed maintenance. With our 500 ton spotting press, we ensure accuracy before the tool is returned to your line.

Die Refurbishment

Whitworth has extensive experience and knowledge of die refurbishment. Quality is key for your tooling and with our help you can extend that life expectancy when programs continue beyond expectancy. Our die service will increase part quality and decrease your downtime when worn tools become an issue. We will partner with your team to create an action plan to get tools back in service as quickly as possible, offering on-site scanning and reverse engineering capabilities regardless of location to maintain your production timelines before you experience an emergency situation. With our 500 ton spotting press we have the capability to ensure accuracy before the tool is returned to your line.

Reverse Engineering & Design

Whitworth's Engineering team is top notch when it comes to scanning and reverse engineering of your tools to reduce expensive downtime with on-site capabilities and state of the art mobile scanning equipment. We can bring our team to yours or if your timeline allows, we can pick them up, scan and return. With up to 8 meters of total measuring volume, size isn't an issue. From the smallest tool to larger die components, we can collect data and create blueprints for your use or use data to build replacements or spares to keep your lines running. Utilizing the latest in 2d and 3d CAD capabilities, our team can tackle any project.

Wire EDM

Whitworth's Electrical Discharge Machining capabilities and our experienced machinists can manufacture your most difficult details to meet your timeline. Our state of the art Wire EDM machines are capable of cutting tight tolerance straight through or tapered shapes and other features with corners having small radii, in a wide variety of metals, including hardened tool steels and exotic alloys.

3D/5-Axis Machining

Whitworth's machining capabilities do not stop at just CNC turning and milling. Our 5-axis machining centers allow our experienced machinists to machine complex shapes and difficult angles in a single operation reducing turnaround time and ensuring accuracy and replication. From mild steel, aluminum, tool steels, to exotic alloys, Whitworth Tool has become a proven leader in CNC milling. With the latest in CAD/CAM technology and tooling we pride ourselves in producing quality parts at the fastest speed possible.

Specialty Die Services

Willy Woods - Sales Engineer

Front Office: (270) 756-0098

Desk: (270) 756-0098 EXT. 5006

Cell: (270) 617-1008

Jesse Lucas - Sales Engineer

Cell: (270) 945-4829

Matt Butler - Sales Engineer

Cell: (270) 863-1972